EXTRUSION

PP granules that pass the MF test and are suitable for production are produced as strips of the desired size and thickness. This process is carried out using state-of-the-art computer-controlled mixers. The system’s dosage adjustment unit mixes the main raw materials and additives in the optimal ratios determined for the product being produced.

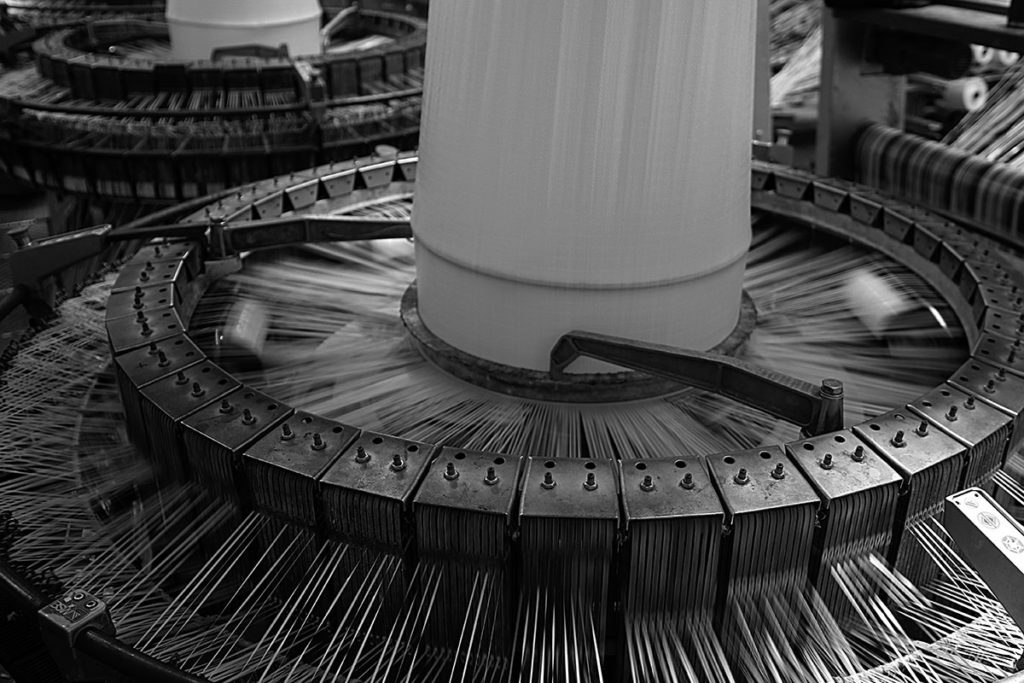

WEAVING

Strip yarns that meet quality standards and pass the required tests are woven into hoses on weaving looms in the desired dimensions. For single-layer fabric applications, ultrasonic edge-cutting systems are activated on the weaving itself, allowing the fabric to be cut along its edges. Periodic width and weight checks ensure timely interventions and prevent faulty production.

LAMINATION

Lamination is applied to the fabrics produced from the woven fabrics in the desired colors and properties.

Laminated fabrics are subjected to periodic adhesion and weight checks. For BOPP coated products, a sandwich lamination system is used, and special additives ensure the product is laminated to the highest standard.